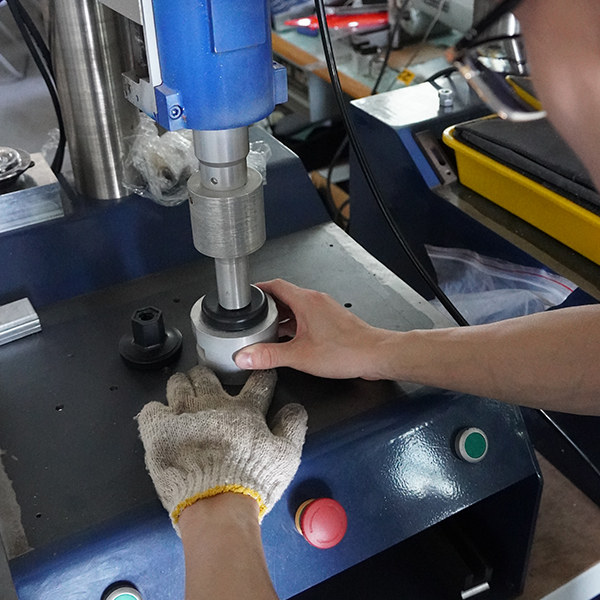

Welding foundry

Welding skills :

Weldability is a function of material structure, contact design, required energy, amplitude of sound transmitter, use and fixation of converter/strong wave transmitter combination.

Easy to weld and compatibility of materials

◈ Most injection molded materials can be welded by ultrasonic wave without solvent, heating or adhesion. The ultrasonic weldability of these materials depends on their melting temperature and thermal conductivity. Generally, the more rigid the plastic is, the easier it is to bond. Low modulus materials such as polyethylene and polypropylene can usually be welded when the sound transmitter is close to the bonding zone.

◈ On STAKING, the softer the opposite, the easier it is to bond. In any case, under the normal combination of amplitude and force, there will be good results.

Design, position and part shape of contacts

◈ Design of joints : The welding of two thermoplastics requires ultrasonic vibration, which is transmitted into the upper half of the assembly by the sound transmitter and passes through the joint of the two joint surfaces. These vibrations can be converted into thermal melting and combining plastics. When the vibration stops, the plastics solidify under pressure, and the bonding of the joint surfaces is completed.

◈ The shape of the two joints, the so-called joint design, is very important for the best result. There are various joint designs, each with its own characteristics and advantages. They are used according to the factors such as the plastic type, the workpiece shape and the required welding, such as I-shape, resistance and sealing, etc.

◈ Joint position : Plastic has wide acoustic characteristics, just like the ultrasonic welding characteristics of an index substance, which are represented by "near domain" and "far domain". "Near area" usually means that the distance between the contact and the surface of the transmitter is 1/4 "(6mm)", and "far area" means that the distance between the contact and the transmitter is more than 10 (254mm). Usually, the closer the transmitter is to the connection area, the faster the welding process is.

◈ Plastics with high elastic modulus also have low internal ultrasonic vibration loss, which allows maximum energy transfer to contacts. Rigid materials are easier to weld than elastic materials, while soft materials do not transmit energy to contacts, and plastics melt at joints under the action of sound transmitters.

◈ Workpiece shape : The general shape of the combined workpiece will affect the welding quality. For the transmission of maximum vibration, the workpiece must have a flat contact surface with the sound transmitter, which must be as wide as possible and continuously surround the contact area.

◈ Interrupt contact between sound transmitter and workpiece will lead to discontinuous welding.

◈ Vibration reduces parts or disappears at turns, corners or discontinuities, such as holes in transmitters and contact structures. These characteristics should be avoided.

◈ For ultrasonic welding workpiece, ribbon shape is most needed, because this structure is easy to share vibration, high stress occurs in sharp inner corner, this frequency leads to brittle crack or sporadic melting, and radial angle is more in line with good shape and actual structure.

Parameter condition setting .PDF

Parameter condition setting .PDF

Various plastic characteristics .PDF

Various plastic characteristics .PDF

Which materials can be melt .PDF

Which materials can be melt .PDF

Problems and Countermeasures .PDF

Problems and Countermeasures .PDF

Rubber characteristics and uses .PDF

Rubber characteristics and uses .PDF

Ultrasonic principle/power supply / Processing head .PDF

Ultrasonic principle/power supply / Processing head .PDF

Explanation of professional terms .PDF

Explanation of professional terms .PDF

Ultrasonic welding technology .PDF

Ultrasonic welding technology .PDF